Westinghouse Electric Corporation

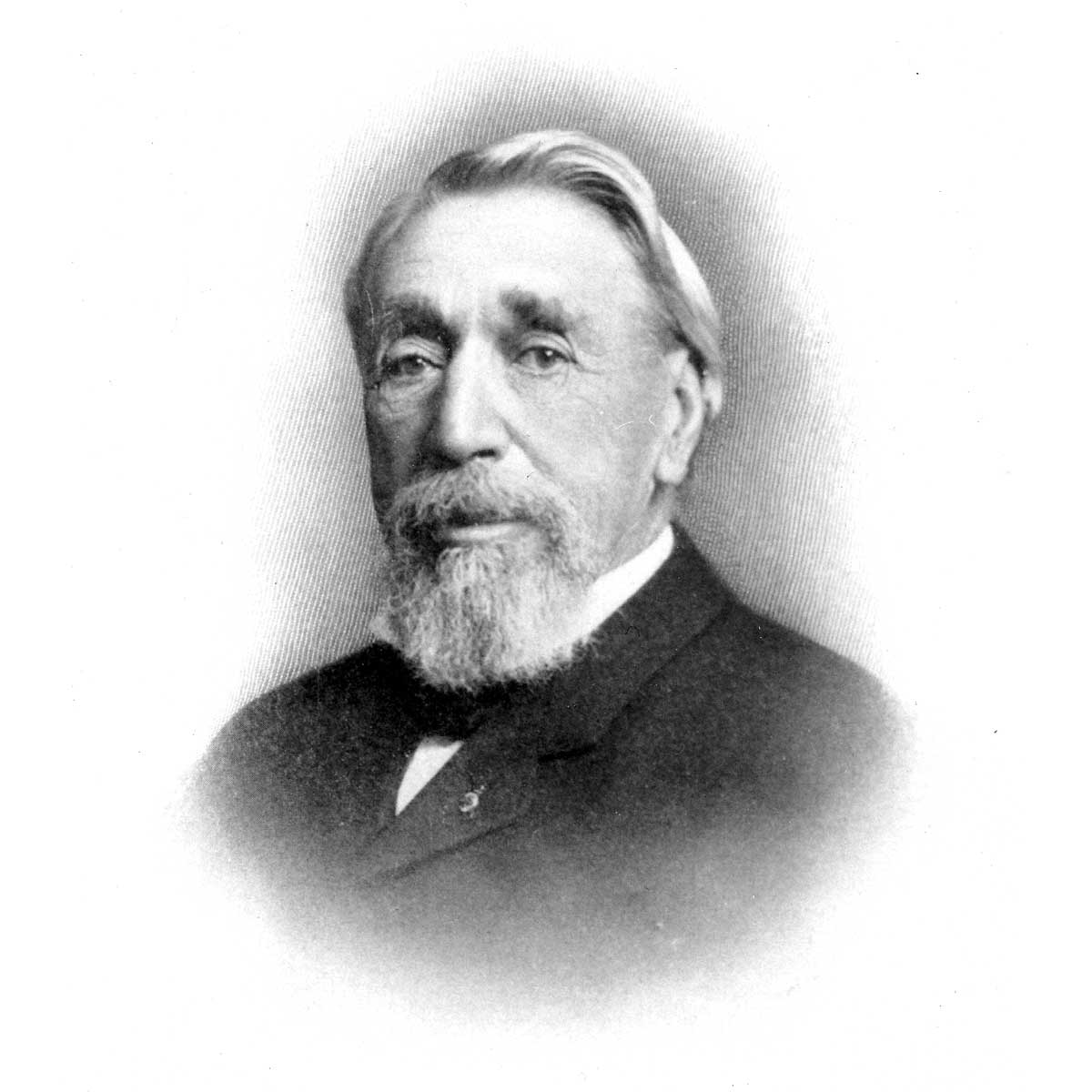

Although most of us associate the Westinghouse name with refrigerators and washing machines. there is much more to the story. The Westinghouse Electric Corporation was once one of the world’s leading manufacturers of electric motors and electrical switching equipment. Its founder. George Westinghouse. made his reputation-and his first fortune-with his invention of the railroad air brake in the late 1860s. It was a device which revolutionized American railroading by halting a fifty yearlong increase in fatalities due to railroad-related accidents.

After founding the Westinghouse Air Brake Company, George Westinghouse went on to develop automatic railroad signaling apparatus that had an equally profound effect on the safety of railroading.

In 1885, Westinghouse co-invented the alternating current transformer. which made long-distance transmission of electricity Possible. In the late 1890s he founded the Westinghouse Electric Corporation, which rapidly became one of the giants of the budding American electrical industry.

Westinghouse was the quintessential American self-made industrialist. A contemporary once remarked of him. “Like a lion in the forest. he breathed deep and with delight the smoky air of his factories … he was transformed into a giant when confronted with difficulties which seemed insurmountable.”

The Proud Circle-W

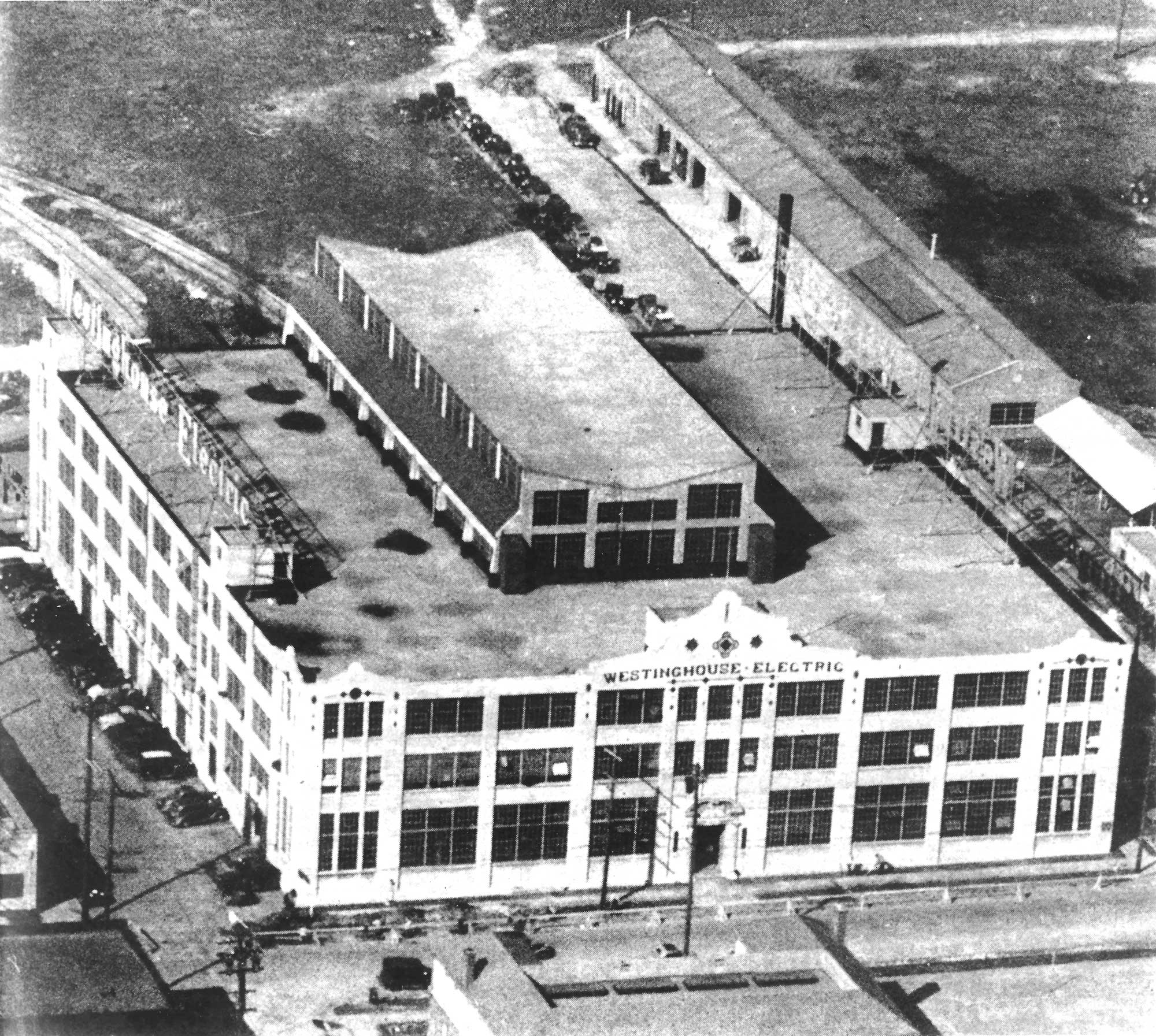

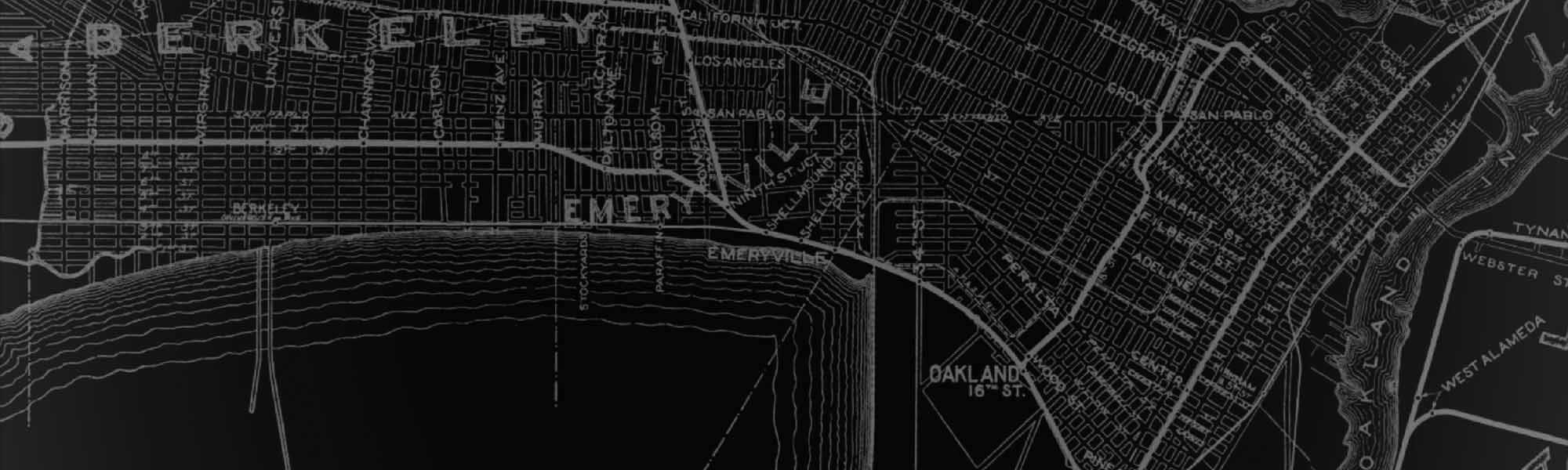

Westinghouse Electric Corporation’s Emeryville facility was constructed in 1924 as a regional warehouse for Westinghouse products, which by this time included light bulbs, home appliances, and many other items in addition to electrical distribution equipment. The building cost $500.000.

The original three-story building was of concrete-frame construction and featured a patented mushroom-head column that was very popular for industrial buildings from the twenties through the fifties. The building’s interior included a four-story-high crane bay with its own spur track for unloading railroad flatcars, allowing massive transformers and other equipment to be brought directly inside for reconditioning.

The three-story Westinghouse plant became an immediate landmark because of its unique Mission-style architecture. The building’s facade had an ornate roof line with a raised center section; each corner displayed the circle W Westinghouse logo, and a large flag emblazoned with the emblem flew high above the Powell Street entrance.

Motors and Micarta

In the 1920s, Westinghouse operated as a service and repair center for electrical equipment. specializing in motor rewinding. coil Winding, meter testing. switchboard building, and steam turbine repairs. A 600-foot wing was added north of the original plant as a result of an 80,000 sq. ft. expansion in 1937, and a 44,000 sq. ft. expansion followed in 1944, bringing the total plant area to 264.000 square feet. The final addition was built of wood to conserve steel for the war effort. During World War II. Westinghouse manufactured and assembled electrical apparatus, including switchboards, control panels. power distribution boards, motors, turbine blowers, and various micarta products.

Unfortunately, in 1924 little was known about how concrete-frame structures would react to earthquakes. Like many other warehouses, the Westinghouse Building was designed for very heavy gravity loads but lacked “shearwalls”-sections of solid wall designed to resist the Sideways movement which earthquakes impart to structures.

The result could be seen after the 1989 Loma Prieta earthquake. The building’s facade was severely damaged, showing the telltale x-shaped cracks characteristic of shear failure. The bases of several structural columns on the south wall were sheared completely through. making repair impractical.

Fortunately, the building was no longer in use at the time of the quake. Soon afterward, the heavily damaged front bay of the building was removed. Faced with astronomical costs for seismic upgrading, the building’s owner opted to demolish the structure instead.

Steve Dirkx

I have a photo from the late 70s, of a small, art deco building , trying to locate it. I think it might be near the Westinghouse factory. It’s welding related. How do I send you a jpeg?

Thanks

Steve Dirkx

Dallas