The Golden Age of Butchertown

The Rise of Butchertown: 1876-1880

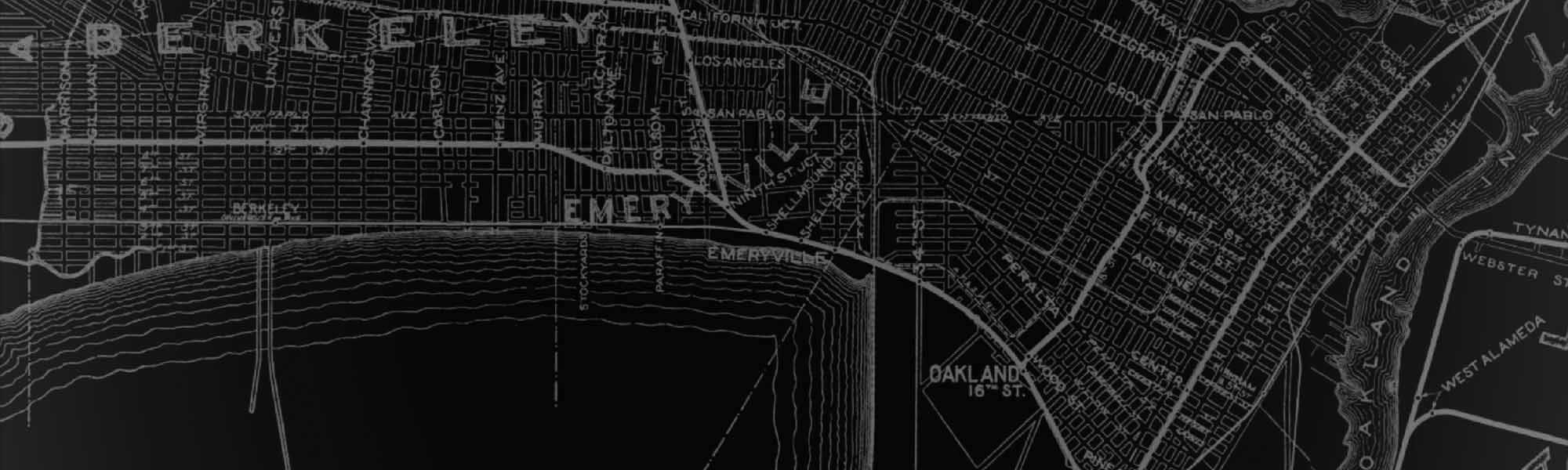

In the nineteenth century, slaughterhouse districts were established on the outskirts of urban areas in order to provide fresh meat for the local population. Before the advent of refrigeration, meat, a perishable commodity, had to be prepared locally so it would not spoil. The first slaughterhouse district in the Bay Area emerged in San Francisco in the late 1860s. Known as “Butchertown,” it was located in the southeast corner of the city, next to the Bay. The East Bay slaughterhouse district, established in the mid-1870s, was also located beside the Bay in an unincorporated, sparsely settled area which later became Emeryville. It also acquired the prosaic name of “Butchertown.”

The East Bay’s Butchertown flourished at this strategic location because of its proximity to the railroad, major highways, and major population centers. The Northern Railway, built 1876-1878, passed through Butchertown, connecting Oakland with Martinez. The railroad consolidated with Southern Pacific in 1898, and after the turn of the century the line was extended eastward to Ogden, Utah. The Northern Railway shipped livestock to Butchertown from remote areas, providing the transportation necessary for the industry to prosper.

The proximity of San Francisco Bay also proved vital to the industry. The Emeryville slaughterhouses were built on pilings over the water so that blood and offal could be conveniently dumped into the Bay and washed away by the daily tides. Furthermore, according to a December 23, 1905 Oakland Tribune article:

“Stock slaughtered here will keep from two to three days longer than meats slaughtered anywhere else in the State, owing to the cool sea breezes which come directly through the Golden Gate.”

Peabody Lane, built by John Allen Peabody in the 1850s, connected Butchertown with San Pablo Avenue, less than a mile away. At the time, San Pablo Avenue was the major highway that ran north from Oakland to present day Richmond. Peabody’s Landing, a wharf located at the foot of Peabody Lane, jutted out in the bay, providing access to maritime shipping.

Wood’s History of Alameda County, published in 1883, has a detailed account of Butchertown’s origin:

“In 1876, H. M. Ames selected a site on the bay out nearly to West Berkeley as a suitable location for a stockyard and slaughtering-house. He began business there in a small way, expecting the railroad to soon be completed to Berkeley so that he could have shipping facilities. But in this he was disappointed for that year, and after a few months gave it up. During the next year the road was built. and the site chosen by Mr. Ames being considered very eligible was decided upon by others who located there, and the business has grown until now the following named gentlemen are engaged in the slaughtering business at this point: Messrs. Grayson, Harrel & Co., Morris & Crow, Stewart & Co., Avey and Watkins. Mr. Avey is engaged in the slaughtering of sheep, and Mr. Watkins in the hog butchering business. The first three firms slaughter about nine hundred animals each. per month. An extensive tripe-works is also located at this point.”

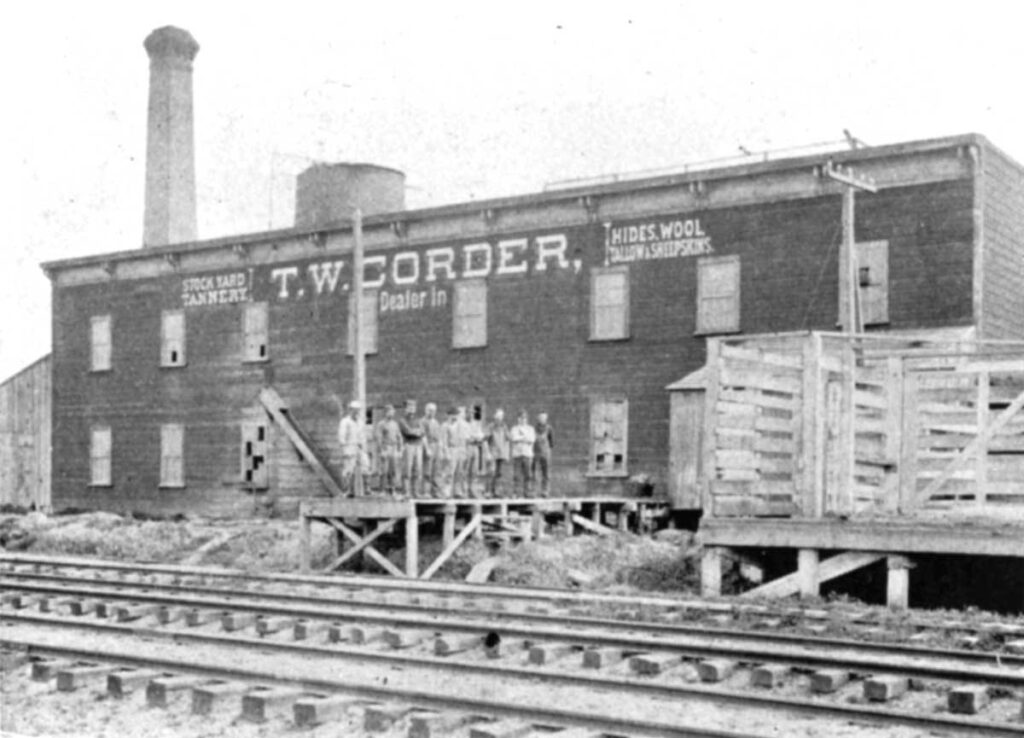

Henry Ames soon realized the mistake of his early departure, and by 1880 returned to Butchertown, reestablishing his business at Bay Street and Dalton Avenue. Thomas W. Corder was another pioneer Butchertown entrepreneur. In 1876, Corder established a hides and tallow business on Peabody Lane and Bay Street. He later formed a partnership with James Cook and established the Cook and Corder’s Tannery and Wool Pullery at the corner of Union (now 67th) and Bay Streets. The factory had a machine called a picker that pulled the wool off sheep skins; the factory also salted hides and prepared them for the tannery. The Corder family operated the business for over 80 years.

Joseph Gaudin established one of the first slaughterhouses in the Butchertown district. Around 1877 Gaudin, originally an Oakland produce dealer, built a slaughterhouse at the foot of Peabody Lane next to the Northern Railway tracks. Gaudin’s slaughterhouse is identified on a map in the Historical Atlas of Alameda County published in 1878. Bishop’s Oakland Directory, 1880-1881 lists Gaudin’s business as a tallow rendering operation (tallow is the fat of cattle that is used in the production of soap). The McKenney’s Oakland City Directory 1883-84 lists Gaudin as a tallow manufacturer with a residence at the stockyards, suggesting he lived on the premises or built a house nearby.

Grayson-Harrell & Co. became the fourth major company to be established in the stockyards district. Consisting of a partnership between George W. Grayson of Oakland and Jasper Harrell of San Francisco, the firm built its wholesale meat operation at the northwest corner of Dalton Avenue (now 65th Street) and Bay Street. The company reorganized in the mid-1880s and, because of a change in the partnership, was renamed Grayson-Owen. The new partnership included G. W. Grayson, J. W. Owen, and J. W. Phillips. By 1887, the company had acquired 14 acres of land, employed from 10 to 15 men, and slaughtered over 1,000 steers monthly. That year. the Oakland Tribune reported that “they (Grayson-Owen) slaughter all day, and the drivers start in at two o’clock in the morning loading their four-horse teams with beef for delivery to the local markets.”

The slaughterhouse district soon became known as Butchertown, and is identified as such on old maps, but after the turn of the century it also was referred to as “The Stockyards.” It consisted of the western portions of the old Landregan Tract, Oakland Homestead, Maxwell Tract, and the Villa Homestead. Early Butchertown stretched from 63rd Street north to 67th Street (formerly Union Street) near the Berkeley line, and from Green Street (now Hollis Street) west to the Bay. This area now comprises the northwest comer of Emeryville.

Butchertown in the 1880s

An 1887 Oakland Tribune article describes the Butchertown of that era.

“Pleasantly located on the edge of the bay. halfway between the city and the town of Berkeley, are the Oakland {sic} Stockyards. The Butchertown of Oakland is a very different place from its neighbor in San Francisco, for it is clean, free from all smell, and has none of the offensive elements of ordinary slaughterhouses about it. To begin with, the buildings project 18 feet beyond the tide mark so that every 12 hours at least all the unpleasant accompaniments of killing sheep and cattle are carried clear out into the rush of water which makes our bay so dangerous for small craft, but so useful in carrying off sewage and refuse matter. There is one smell however, in the stockyards which is unavoidable and is confined to one particular building, and that is the tallow-house or Trying Works, where the skins of slaughtered beeves yield neatsfoot oil, the skin and sinews of the feet glue, and enormous quantities of fat are tried out into countless casks of tallow. Not a bone of a beast is lost, for the hoofs go to China to be converted into buttons, and the loins go East, to return in the shape of combs, while the heads are cooked until the meat drops off and the soft bones are burnt into ashes and sacked and sold to be ground as fine as flour and then molded into crucibles for the Mint or for assaying works and refineries. The hard bones, the knuckle bones and jawbones, and the shinbones are burnt black and utilized at one stage of the process of refining sugar.

The stockyards community is always busy and apparently very contented. The system of driving the cattle into the corral is very perfect and their death is as painless as it is sudden. Imagine a large slaughterhouse, with a small engine working a windlass on one side and a rope running from it to a heavy snatch-block firmly fixed in the middle of the floor. At the end of the rope is a noose, and at the further side is the corral in which are the beeves. There is plenty of slack rope and the butcher opening the gate throws the noose over the horns of the nearest beast. Once around his neck, the little engine winds up the slack, and the steer, after a few ineffectual struggles, is jerked into the middle of the floor before he knows what has happened. One crashing blow with the pole of an axe on the center of the forehead and he knows nothing more. The great beast falls over like a prize fighter knocked out, and a minute after his throat is cut, and two men are busily taking his hide off. Three or four more blows are given after the steer is knocked down, but the beast is utterly unconscious of them. The skull afterward shows the exact mark made by the axe which causes instantaneous death. The engine is again called into requisition to haul the carcasses into rows, and the ordinary work of dressing is proceeded with. The hides go to the tanners, the fat and bones are disposed of as described above, and the tide carries off the offal.”

An 1888 Oakland Tribune article details the sights and sounds of early Butchertown, a gruesome business which only visitors with a strong stomach could tolerate:

“If you have eyes fit for heroic sights, and do not pale at the sight of blood or sicken in heroic smells, you will find much of interest at the abattoirs–out at the station called The Stock Yards, a mile or two toward Oakland from West Berkeley. Here are slaughtered the cattle and prepared the meats which go to feed the carnivorous bipeds of three cities and a score of hamlets. What with the low moaning of doomed cattle, the shrieking of swine, the plaintive bleating of sheep, the swish of the knife, the thud of the descended ax, and the gurgle of escaping blood, the yards are steeped in a potpourri of sound fit for melodramatic action.

At the yards Grayson, Owen & Co. butcher about 1200 steers and 200 calves monthly, with an annual output of some $500.000; J. Walsh kills an average 100 sheep and lambs daily for Miller & Lux, and at times fifteen or twenty hogs; Hayes & Co. put out the lives of about a thousand cattle each month and do an annual business of half a million dollars; Crummey & Hall’s branch establishment does a yearly business of about $70,000 in slaughtered sheep and hogs, though the firm’s entire business involves the killing of from 7,000 to 10,000 sheep monthly and an annual output of $400,000; John Stewart, the pioneer butcher, does an annual business of $75,000 in slain sheep, and Eugene Avy kills the same animals to the extent of eighty to 125 a day; Martin M. Samson converts some 650 hogs into pork every month, and Hourat & Co. perform the same change on from twenty to twenty-five squealers each day.

In connection with the butchering are other important industries. Cook & Corder have a large wool pulling establishment, a tannery, and a bone burning kiln, with an annual output of $120,000. At Lacosta & Mounicot’s works some 240,000 sheep’s tongues and brains and 24,000 tripes are annually prepared for market. This firm also reduces heads and offal to glue and tallow. J. G. Corder’s glue works turn out some 240,000 pounds annually, and Joseph L. Gaudin does a large business in tallow, which he tries and rends. The house of Hofman, Woenne & Eichelbaum, or the California Sheep Casings Company, cleans, cures, and prepares for the market all the intestines of sheep and cattle.

And with all this varied industry the abattoirs are unusually clean, the flowing tide carrying out all the discarded bits and offal, so that there is no carrion to pollute the atmosphere. The only stench is that necessarily arising from the tallow vats.”

At the time this article was written, the traditional method of slaughtering and processing meat in the Bay Area was about to change. In 1887, Gustavus Swift arrived in San Francisco, and within a short period of time revolutionized the West Coast meatpacking industry. Swift had built the Swift and Co. meatpacking complex in Chicago, a modern facility which introduced machinery and refrigeration into the meatpacking process. In 1892, Swift built a huge $2.5 million, seven-story plant that covered eight acres in the town of Baden just south of San Francisco. The plant, known as the Western Meat Co., incorporated refrigeration, machinery, hoists, and the other labor-saving devices that Swift had perfected in Chicago.

The Western Meat Co. undercut the price of meat produced both in San Francisco and in the East Bay’s Butchertown, resulting in a “meat war” that lasted for years. Local wholesale butchers organized the Butchers’ Board of Trade and warned Bay Area consumers that refrigerated meat was “highly dangerous to the public health.”

However, the advantages of refrigeration and mechanization could not be ignored. After the turn of the century the larger wholesale meatpacking plants throughout the Bay Area adopted Swift’s innovative methods of meat processing.

7,000 Sheepskins a Month

The T. W. Corder Wool Pulling Works and Tannery, one of Butchertown’s first businesses, was established in the 1870s and survived into the post-World War II era. This factory remained under the ownership and control of the Corder family during its entire existence.

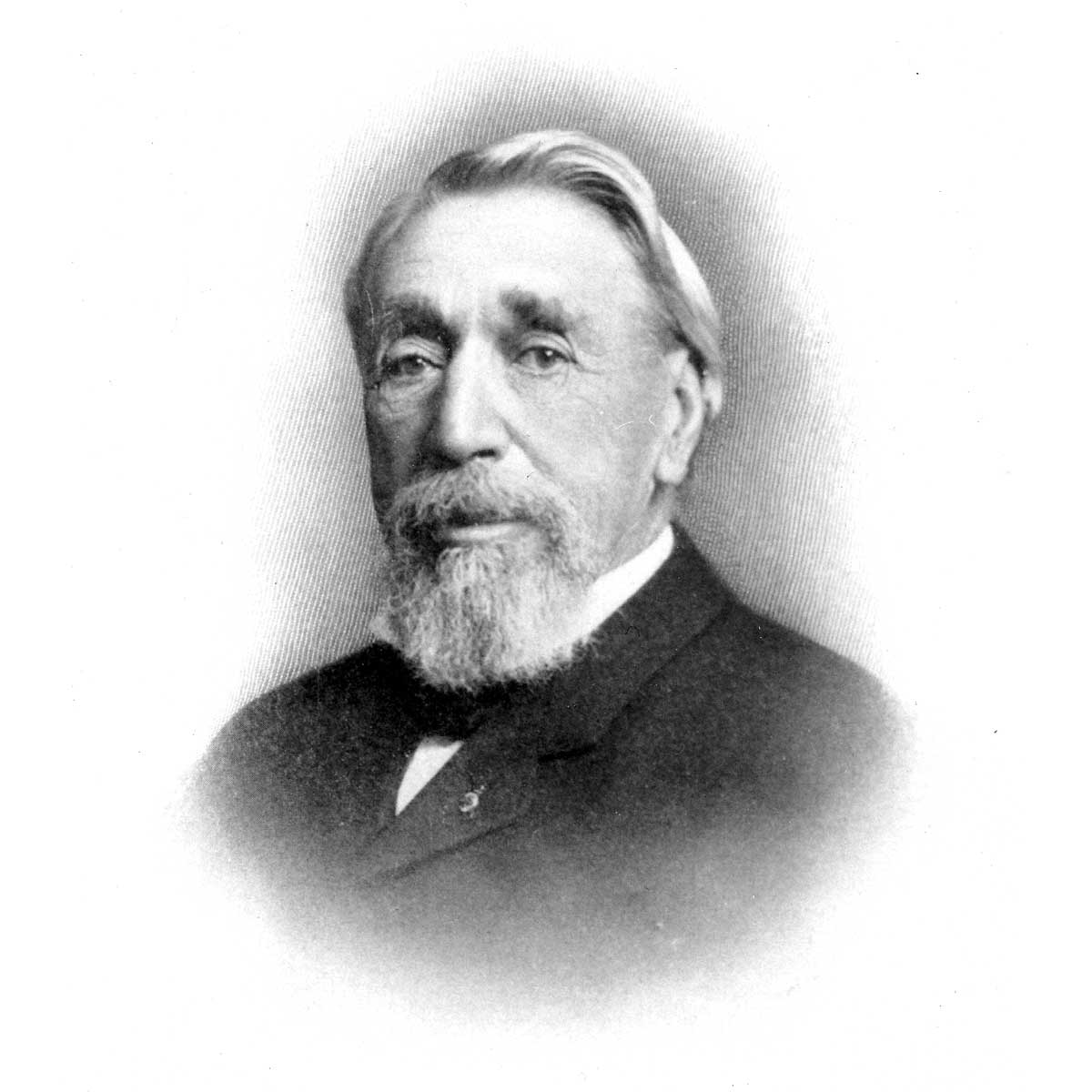

Born in England in 1820, Francis Corder immigrated to California in 1854 with his wife, Mary Ann (Hawes) Corder, and two sons. The Corder family settled in Butte County, where Francis worked in the mines and later operated a boarding house for miners. The family moved first to Marysville and later to San Diego, where Corder became involved in the wool business, an occupation acquired in his native country.

About 1874, the Corder family moved to Oakland, and a year later Francis established a tannery and wool pullery business. Corder’s Tannery and Wool Pullery was located at the foot of Union Street (later 65th Street) near the Northern Railway tracks. Francis Corder died in 1887, and his wife Mary Ann died in 1892. Thomas, the second son, inherited the business. Thomas Corder formed a partnership with James Cook, and the business became known as Cook and Corder’s Wool Pulling Works and Tannery. Corder married Nettie Farley in 1873, and they had three sons and a daughter.

The original plant was a two-story, wood plank L-shaped building with a tall brick chimney at the northeast corner. A loading platform extended from the building to the nearby railroad tracks. On the south side of the building was a large platform for drying wool, along with another platform on the flat roof that served the same purpose.

The process of cleaning the wool required large amounts of water, which was pumped from three artesian wells by steam engines and stored in a large tank mounted on the roof of the plant. These wells also provided water for all of Butchertown.

An 1887 Oakland Tribune article describes the Cook & Corder’s Wool Pulling Works and Tannery operation.

“In addition to the trying works located next to Hayes & Co., Mr. Corder owns extensive wool-pulling works and a tannery close to the Stockyards Station. He buys all the sheep-skins, pulls the wool off, and has it graded ready for the scouring mill. Sixteen men are employed here and at the Trying Works. No pulled wool is used on this coast, the material, when perfected, being baled and sent East. About 20,000 to 25,000 lbs ., or from 5,000 to 7,000 skins are pulled monthly. This house also salts all the hides in Oakland, and makes them ready for the tanners. Reckoning 300,000 lbs. of wool as the annual amount pulled, the output from this source, at a medium average of 30 cents per lb., is $90,000. The shrinkage in pulled wool is from 1/3 to1/2 less than that of fleece-wool. To be more precise. pulled wool is sold on a guaranteed basis of 38 per cent shrinkage, whilst fleece-wool has a shrinkage from 50 to 80 per cent. The wool is packed in bales, weighing about 500 lbs., square and compressed. Two burring machines, one wool picker, one scouring machine and one bark mill and a roller constitute the principal machinery of the works, the value of the plant being $15,000 and the total output being about $120,000 per annum. A thirty-five horse power engine, built by Prescott, Scott & Co., runs the machinery, and two steam pumps are in operation which raise water for all Butchertown from three artesian wells, which are 200 feet, 84 feet and 48 feet deep, respectively. The burrers are combined with washers which sprinkle the skins whilst eliminating the burrs with blunt knives making 1,300 revolutions a minute. The wool is pulled out and put in a dryer fifty feet long and eight feet wide, supplied with exhaust steam from the engine. This furnishes, of course, the heat. The picker loosens out the wool, and a scouring tub with seven rollers washes the dirty wool after it is picked. There is another drying room, thirty feet by twenty feet, heated by pipes, which dries three hundred pounds of wool per diem, at a temperature of one hundred degrees. The wool is graded into eight different kinds and all eight grades can come from one sheep.”

“The buildings are two stories in height and stand on ground one hundred feet by sixty feet. After the burring process the hides are put in two close rooms, an antiseptic mixture being rubbed into them to preserve the sheepskins. Being almost hermetically enclosed in airtight compartments, they generate their own heat. Sheepskin, as is well known, is put to a variety of uses-for binding books, parchment, children’s shoes and all sorts of leather work. Outside the wool pulling works are stacked the beeve’s skulls and the horn-peths (the bone from which the horns have been knocked off). When this circular pile reaches sixteen feet in height by twenty feet in diameter, a woodpile is kindled to windward and about twenty tons of bone are reduced to eight tons of ashes, which once kindled burn right out…All the coal, salt and hay used here is delivered right at the little wharf known as Peabody’s Landing. Cook & Corder own or lease nearly all the tide lands at the Stockyards and are constantly building as fresh slaughterhouses are required.”

Butchertown Prospers

By 1880 Butchertown had evolved into a distinct community, the boundaries assumed a definite shape, and the place name “Butchertown” appeared on contemporary maps. Newspapers soon recognized Butchertown’s contribution to the local Bay Area economy, and numerous articles appeared on the subject. Passengers on the Northern Railway main line and the West Berkeley line passed through Butchertown on a daily basis, and so large numbers of people became aware of the growing Stockyards community.

The San Francisco stockyard district suffered two disasters that contributed to the growth of East Bay’s Butchertown. On May 31, 1890, San Francisco’s Butchertown was destroyed by fire, presenting Butchertown with an opportunity to increase meat production. San Francisco’s facility was rebuilt, but sixteen years later the great 1906 earthquake shook the slaughterhouse buildings off their pilings onto the mud flats, and once again a meat shortage developed. In 1908, city health authorities investigated San Francisco’s Butchertown and found conditions to be deplorable. Authorities ordered six slaughterhouses to be destroyed because the accumulation of dirt and filth attracted large numbers of rats. San Francisco’s Butchertown had difficulty recovering from the earthquake disaster and the scandal of 1908. In the meantime, its competition in Emeryville prospered and by 1914 controlled 90 percent of the Bay Area meat-packing business.

The prosperity of Butchertown can be attributed in part to the laissez-faire attitude of local government. The area north of Oakland in which Butchertown was located remained unincorporated until 1896. In December 1896, an election was held to decide if Emeryville should become a town. The proprietors and employees of Butchertown supported incorporation, fearing annexation by Oakland. They were afraid that if Stockyards became part of Oakland, the city would declare Butchertown a nuisance and eliminate the industry. This fear was well founded; sixteen years earlier Oakland had shut down the slaughterhouse district in East Oakland.

The election was held on December 2, 1896; incorporation passed 152 to 28, and Emeryville became a town. The Town of Emeryville did not interfere with the meat-packing industry, and Butchertown continued to grow and prosper after the turn of the century.

Butchertown remained a distinct community after Emeryville’s incorporation. The opening of the Stockyards Post Office, established in March 1898, helped place Butchertown on the map. Byron W. Alden, who became the first Postmaster, also worked as a weigher for the Oakland Meat and Packing Co. The Stockyards Post Office remained in operation for only eleven years, closing in July 1909. Letters and postcards with the Stockyards postmark are rare and are in great demand among California postmark collectors.

Golden Age of Butchertown

Butchertown experienced a golden age which lasted from about 1880 to 1930. During this 50-year period, several meat-packing plants and byproducts factories, both large and small, came into existence, dramatically expanding production. The smaller operations included Chin Fook & Co., F. Carnes and Co., U. M. Slater, and Byron Alden. Larger firms included Oakland Meat and Packing Company, and Bayle-LaCoste and Company. Grayson-Owen, one of the first companies established in Butchertown, continued to flourish. The larger meatpacking plants often maintained extensive facilities including stock corrals, feed sheds, hog pens, and cattle pens.

Urotes M. Slater and his brother William built a slaughterhouse at the foot of 65th Street in about 1891. The Slater brothers specialized in butchering hogs, sheep, and calves. The first year in business U. M. Slater, Inc. killed 500 hogs, 500 calves, and 2,000 sheep. By 1905, according to an Oakland Tribune article, annual production had greatly increased.

“At present (1905) the killing has reached a total of 120,000 sheep, 6000 calves and 8.000 hogs annually, supplying the trade in San Francisco, Oakland, Alameda, Berkeley.”

“Besides slaughtering this amount. Mr. Slater also buys and sells large quantities of livestock in the county. His place of business at the Stockyards is admirably situated for slaughtering purposes, being located on the bay shore where the strong tides wash away all refuse matters, making its sanitary condition perfect.”

The slaughterhouses of U. M. Slater, considered ‘models of cleanliness,’ were washed down every night with chemicals. This company bought and sold cattle and also shipped veal, mutton, and pork to Bay Area consumers. The Slater brothers lived on Dalton Avenue (now 65th Street) in Butchertown. The firm last appears in the Polk’s Oakland City Directory, 1930, suggesting the business closed as a result of the Great Depression.

John Breuer & Co. specialized in the production of beef and sheep casings used in the manufacture of sausages. The firm, established about 1890, was located at the foot of 66th Street. According to a 1910 Oakland Enquirer article, Breuer had “striven to earn a reputation for delivering only perfect goods and this they have succeeded in doing.”

Pierre Loustalot, another enterprising wholesale butcher, originally worked as a salesman for Miller & Lux, the California cattle barons. Having learned the business there, Loustalot opened his own slaughterhouse in Butchertown about 1897 at Bay Street near Dalton Avenue; he lived on Dalton Avenue near the corner of Green (Hollis Street) in Butchertown. Loustalot eventually lost his business and later worked for F. Carnes & Co. as a foreman. He died about 1912; in 1914 his widow, Rosalie, opened the L. & L. Hotel at 1318-65th Street.

The F. Carnes Company, operated by Ferdinand Carnes and Frank Caselet, was located at the foot of 65th Street next to Bay Street and the Southern Pacific tracks. Established in about 1896, F. Carnes Company, like U. M. Slater Inc., only slaughtered calves, hogs, and sheep, mostly brought from Nevada. By 1906, the company was butchering 48,000 sheep, 6000 hogs, and 3,000 calves per year, and distributing mutton, pork, and veal all over the Bay Area. In 1914 the Carnes Company employed fifteen butchers. Carnes closed the Butchertown operation about 1916 and later opened a wholesale meat store at 5831 San Pablo Avenue.

A 1905 Oakland Tribune article on Butchertown declared:

“One of the most noticeable evidences of the growth of Oakland and its environs is to be found in the thriving appearance of the Stockyards of ‘Butchertown,’ where one of the most prosperous industries of Alameda County is located. From an insignificant group of small slaughter houses, this place has, in a few short years, become the center of a colony of stock handlers that not only supply the meat consumers of Oakland, Berkeley and Alameda, but a vast number of interior towns and even invade the markets of San Francisco in competition.”

In 1906 the Oakland Enquirer similarly raved:

“…the Stockyards, located in Emeryville, just a short distance west of the Oakland city boundary line, are continually furnished with an abundant supply of fine beef cattle, fat hogs and sheep.

Not fewer than four firms are there located in the business of preparing fresh meat for the local markets. The site is ideal. It is at the shore line of the Bay of San Francisco, is swept continuously by the cool winds which enter the Golden Gate, thus having the atmosphere cleansed and purified every hour of the day and night. The ground slopes towards the bay allowing of perfect drainage. Recurring tides carry away into the sea all refuse which may not be utilized in the by-products of the abattoirs. Under these favorable conditions the Stockyards are models of cleanliness. And the firms doing business there maintain the reputation of the locality by carrying on their several business ventures in the most sanitary manner possible. The most recent appliances for hauling meats are made use of, and the very choicest cattle, sheep and hogs are obtained from the interior ranges of the state with which to supply the teeming population of this county, and, in part, San Francisco, as well.”

Byron Alden, “one of the finest men in the community,” operated a wholesale slaughterhouse at 65th and Bay Streets as a branch of the Miller and Lux firm. The Germans, Henry Miller and Charles Lux, dominated the livestock market in California at the tum of the century. According to a 1910 Oakland Enquirer article, Alden’s modem plant slaughtered only the best sheep, hogs, and cattle, and had the reputation of being unusually clean and sanitary. By 1914 the firm employed ten butchers, and its products were distributed all over the East Bay.

Oakland Meat & Packing Company

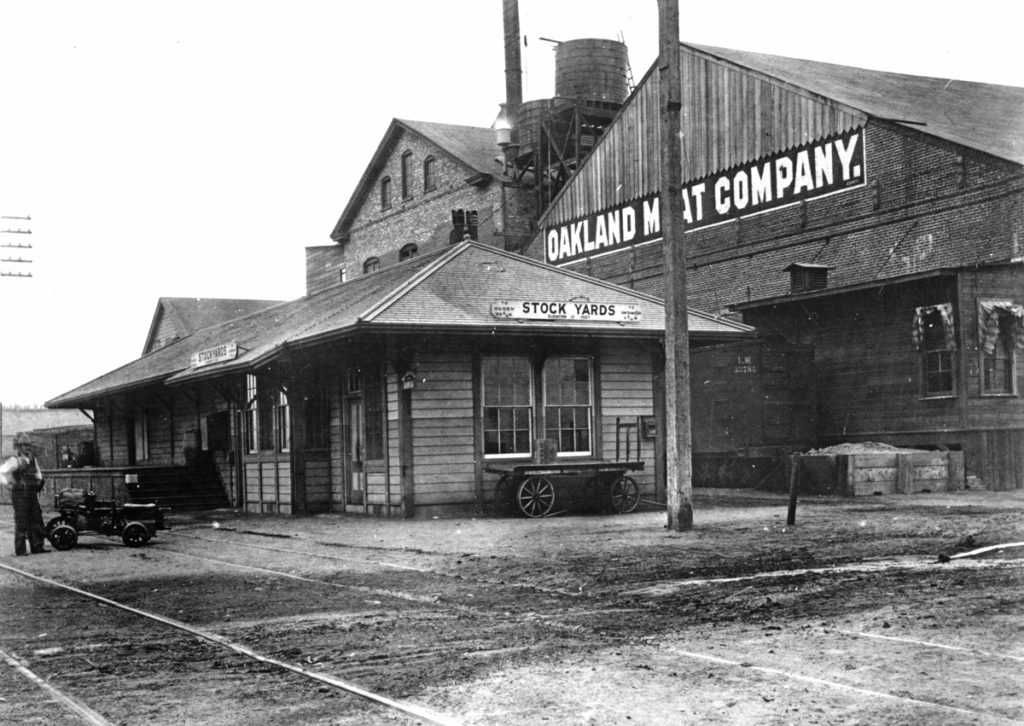

Oakland Meat and Packing Company was established in about 1898 at the foot of Dalton Avenue, and soon became the largest firm in Butchertown. In 1906 the Oakland Enquirer said of the firm:

“The Oakland Meat & Packing Co. is the third largest in the United States west of Denver, and one of the largest on the Oakland side of the bay. It does the largest livestock commission business of any of the meat companies in the state. The officers of the company are J. F. Reynolds, President; S. D. Prather, Vice-President…The plant and the yards of the company at stock yards cover eight acres of land along side of the Southern Pacific Railway. New brick buildings equipped with the most modem machinery have recently been erected, and the new coolers have a capacity of twelve hundred carcasses.

The killing capacity of the plant is 500 cattle, 350 hogs and 300 sheep per day. The stock handled or slaughtered by the company comes from Oregon, Nevada and California. Over 100 men are employed by the company, and forty horses are required to haul the ten large delivery wagons used to haul the beef, pork, and mutton to the retailers or to ships and steamers, or to freight depots. Several of these wagons have a capacity equal to that of the ordinary refrigerator cars. This company is now preparing for shipment to all ports of the world tallows and greases; are also shippers and large exporters of polished bones which are made by manufacturers into fancy ornaments, knife handles, toothbrushes, and piano keys. The horns and hoofs after being skillfully processed are shipped to manufacturers of fancy articles. From the blood and the residue after trying out the tallow and greases, is made the fertilizers which are now the salvation of the orchardists and the vineyardists of the state, and large quantities are being shipped daily to benefit and nourish the impoverished soils of the fruit districts. Boat loadlots are also being shipped to the Hawaiian Islands, where the cane growers are eager to secure the goods that bear the Oakland Meat & Packing Co.’s brand. Tons and tons of poultry foods such as dried blood, meat meal and bone meal are being shipped daily to the large poultry farms throughout the state…

The hides are salted down in cellars scientifically built for the purpose. With this arrangement the cure given the hides make them much more valuable to the tanner than those not so well cured, and the Eastern tanners are now eager bidders for the hides of this company, but so far the California tanners have had the preference when sales are made

The machinery throughout the plant is propelled by electric power furnished. over private wires from the large generators of the Bay Counties Power Co.

Not until recently has the public of Oakland and vicinity had the opportunity to witness the inner workings of a large packing or slaughter house, but now strangers may see the bullock, hog or sheep in all the different stages as it travels from the chute which lead to the killing pens on the third floor to the electrical device which conveys the carcass to the sweet and clean coolers in which the beef, pork, or mutton hangs on long rails, and is inspected by the retail merchant or jobber who selects that which will best please his patrons. A large office force is required to keep the records of this ever growing business. Through the efforts of the Oakland Meat & Packing Co. the Southern Pacific Railroad Co. has been induced to erect a large new freight and passenger depot at Stockyards. This depot was built within a few feet of the plant in order to more conveniently handle the large freight and express business that is being built up by the packing company. As many as eight cars per day have been loaded from the long track docks.”

By 1910 the Oakland Meat & Packing Company, according to the Oakland Enquirer, had become the largest meat-packing plant in the Stockyards district. “The importance and growth of Oakland is well demonstrated in the plant and business of the Oakland Meat and Packing Company (Inc.), which is the largest institution of its kind on the continental side of the bay west of Denver. The plant is of brick and is unsurpassed anywhere in its arrangement and appliances, and it has a monthly capacity of 5,000 beeves, 1,500 hogs, 1,500 calves and 7,500 sheep, and is constantly worked to the limit of its capacity. The company handles only fresh meats but uses all materials in the manufacture of by-products, in which it does an extensive business.”

The company occupied an eight-acre site which included a stockyard south of 66th Street. Because of its proximity to the Southern Pacific tracks and the railroad freight station, the plant had excellent shipping facilities and received livestock by the train load.

By 1932 the Oakland Meat and Packing Company had expanded and employed over 200 workers. The plant slaughtered only the finest livestock, hogs raised in Nebraska, sheep from California, and cattle raised in Colorado. The firm produced bacon, hams, and sausage sold under the “Shasta” brand as well as lard sold under the “Oakleaf” brand. In 1932, the company operated a fleet of 75 trucks that delivered fresh meat to local retail meat markets. It also processed animal by-products to make meat meal and bone meal for poultry farmers. The company maintained high standards of sanitation and invited visitors to inspect the plant.

Grayson-Owen

Grayson-Owen remained a major packing house into the twentieth century. By 1906 the firm had built a new slaughterhouse that measured 96 feet by 125 feet, featuring a ventilation system so efficient that the inside temperature of the building fluctuated only 15 degrees the entire year. The new plant had a refrigerated cooling locker where 400 beef carcasses could be frozen and stored. In 1906 the plant slaughtered 3,000 head of cattle per month and operated extensive corrals and stock feeding sheds located south of 65th Street.

A 1906 Oakland Enquirer article about the Grayson-Owen slaughterhouse noted:

“The abattoirs stands on the beach of the bay which is of hardpan with a gravel dressing. On the bay side is located the chute through which the luckless cattle are driven to the killing pen. A single slight blow with the pointed end of a sledge-hammer instantly causes unconsciousness and an almost painless death. The beef carcass is hauled into the adjacent room through a door which is hoisted by automatic machinery, and there the carcass is speedily dressed. The daily output of this abattoirs is about 75 head of cattle, but the capacity is fully 150 head. In dressing the carcasses, the hides, heads, legs, blood, and other by products are separated, each being dropped through a separate chute into the basement and there prepared for shipment. Blood and bones are utilized for fertilizers, hoofs for glue, shin-bones give up their marrow for oil…”

Bayle, LaCoste & Company, Inc., located at Bay and 63rd Street in south Butchertown, was owned by J. Bayle, J. LaCoste, P. Bareillies, and J. Bareillies. Established about 1885, the company processed animal by-products from the various meat-packing plants in the district, and by 1914 had 18 employees. According to a 1914 ad, the firm also sold “tripe, calve’s heads, and brains, tongues, feet, sweetbreads, livers, and oxtails.” In 1921 Bayle, LaCoste produced about 250 tons of fertilizer and chicken feed per month. The fertilizer was manufactured from animal by-products and the chicken feed derived from blood. Al LaCoste was president of the company and also served as mayor of Emeryville from 1936 to 1964. The Bayle-LaCoste meat-packing plant was destroyed by fire on July 20, 1940.

Chin Fook & Co., a firm owned and operated by Chinese, became the only ethnic business in Butchertown. Chin Fook processed pork that was sold to Chinese and Japanese butchershops in the Asian community. The business had seven employees in 1914. Chin Fook also owned a meat market at 387 9th Street in Oakland.

The T. W. Corder and Wool Pulling Works continued to flourish during the Golden Age of Butchertown. The business expanded after the turn of the century, and by 1914 the firm employed 30 workers. A new two-story brick building, 80×110 feet, was constructed on the property in the 1920s.

Thomas W. Corder died at Merritt Hospital in September 1928 at the age of 83. leaving an estate worth $1,000,000. According to an obituary, Corder was one of the founders of the Bank of Italy (originally the Security Savings Bank) and was also “was one of the group of bankers who assisted in the establishment of the Hotel Oakland.”

Walter E. Corder, the son of Thomas W. Corder, operated the business until he died in 1953 at the age of 71.

Progress in Butchertown

Evidence suggests that unsanitary conditions prevailed in early Butchertown. An Oakland Enquirer article dated June 21, 1889 describes Butchertown as having an “odoriferous atmosphere” because of a lack of cleanliness. In contrast. J. H. McMenomy operated a slaughterhouse located nearby on San Pablo Avenue that was a “model of neatness.”

“The country about Butchertown has been noted for the odoriferous atmosphere for about a quarter of a century…large slaughterhouses have been erected…on the shore of the bay. At times a strong odor is wafted from there to the country towards the hills. Some days the stench from the slaughterhouses and the soap works there is such that the air is impregnated with it to such a degree that residents near the foothills get a faint sniff of it.

A recent visit of an Enquirer representative to Golden Gate convinced him that if the proprietors of the establishments about Butchertown and West Berkeley would only keep their places clean, the stench would either cease altogether or be so light that it would be almost imperceptible. On the occasion named, the reporter visited the establishment of J. H. McMenomy on San Pablo avenue, and was shown all through the place. The building where the cattle are killed is a model of neatness. Not a speck of dirt was to be seen anywhere within the building…All the yards and barns on the place were also clean…

If the owners of other establishments would take only half the trouble in removing all refuse and dirt from their places their places would be greatly improved. They would well take lessons from the premises of Captain McMenomy.”

Several important developments took place after the turn of the century that revolutionized Emeryville’s meat packing industry. A revolution in transportation occurred when the motor-driven truck replaced the horse-drawn wagon. The construction of brick buildings equipped with advanced machinery and refrigerated meat lockers contributed to the modernization of the meat packing industry, and the introduction of meat inspectors reduced the danger of contaminated meat entering the marketplace.

By 1906, Butchertown proprietors practiced sanitary methods of slaughtering and butchering livestock. according to the Oakland Enquirer; “Up to date scientific and sanitary methods have taken the places of the old-time methods. Boards of health can no longer find fault with the abattoirs from which is supplied the daily meat-food of the inhabitants of the most thickly settled portion of Alameda County.”

The new Butchertown meat packing plants had refrigerated locker rooms so that entire beeves could be refrigerated, thus eliminating the need to ship meat before it spoiled. A 1906 article provides information about the Grayson-Owen refrigeration plant. “The temperature in this establishment varies not more than fifteen degrees throughout the year, being always cool with the exception of a very few days in mid-summer. Besides the building contains an ample refrigerating plant supplied with a direct-expansion compressor whereby the temperature is maintained steadily at 38 degrees never rising above 40 degrees. In the refrigerating department beef carcasses may be kept weeks if necessary, though usually for only five or six days. Some customers prefer beef not refrigerated and for these a separate corridor is provided where carcasses are hung over night, permitting them to cool and all moisture to evaporate before submission to the process of refrigeration. This process insures hard, clean and sweet beef.”

A 1914 Oakland Enquirer article about Emeryville industry describes the modem meat-packing plants of Butchertown:

“An important section of Emeryville is designated as ‘Butchertown,’ and ‘the Stockyards,’ and there ninety per cent of the meat consumed in the bay region is prepared for he market. The stockyards are located in the west end of the town along the bay shore, and in the various packing houses adjacent thereto are slaughtered and prepared for the local retail markets the beef, mutton and pork and their by-products consumed. Over two hundred men are employed in the industry. The total payroll is $20,000 a month, or about $250,000 a year. Fifty thousand head of beef, representing $3,000,000 are slaughtered annually, together with 250,000 sheep, 200,000 hogs and thousands of calves.

Thousands of tons of fresh meat are shipped daily from the several establishments to dealers in all the bay cities and by those in the packing industry, and millions of dollars are involved yearly in the conduct of the business. Such well known firms as Miller & Lux, Grayson, Owen & Co., the Oakland Meat Company, F. Cames & Co., C. M. Slater. Inc., Bayle, Lacoste & Co., Peterson Bros., and Chin Fook Company have for years operated in this district and are increasing their business every year. All of the plants are equipped with the most modem packing machinery, together with cold storage and all the other essentials for the modern methods of wholesale butchering. The Cames Company handles mutton only, the Slater Company sheep, calves and hogs. Chin Fook & Co. deal in pork only and do an immense trade in the Oriental quarters of the bay cities, their retail shops supplying not only the Chinese and Japanese but also many persons of other races. Bayle Lacoste & Co. devote their establishment to preparing tripe for the retail trade of the bay cities.

As an adjunct to the packing business of Emeryville, T. W. Corder many years ago established a wool scouring plant at the stockyards, buying the fleece of the sheep. This business now occupies a large two-story brick building and is flourishing splendidly.

The packing business of Emeryville by the above firms has grown year by year as the bay cities’ population increased. It is estimated that not less than $250,000 are annually paid out in wages to employees at the yards and packing plants; the livestock purchased from California growers nets the latter at least between $3,000,000 and $4,000,000 annually. The by-products shipped from the plants-bone, glue, soap material, hair, neat’s foot oil, horn for buttons and knife handles and a dozen other things, represent a total value of $1,500,000 every year. The maintenance of these big meat packing plants and the transportation of their products to the retail markets requires many teams and drivers. These teams must have hay, grain and foodstuffs and their drivers and caretakers be fed all of which puts money into the pockets of farmers and dealers in the commodities mentioned.”

Another major change took place in transportation. In early Butchertown horse-drawn wagons hauled the meat to local retail meat markets. The stout wooden wagons had high, ribbed sides and large spoked wheels, and were pulled by two horses and driven by a teamster. The wagons remained in service into the twentieth century, although motorized trucks began to replace them in the teens. By 1920 the horse-drawn meat wagon had disappeared from the streets. In 1920, the Oakland Tribune Yearbook reported: “All deliveries are now made by motor vehicles, horse conveyances having been completely abolished.”

The old name of “Butchertown” with its negative connotation no longer seemed to apply to this progressive community. and gradually the name came into disrepute. After the turn of the century the new name “Stockyards” became the preferred term for Butchertown.

The Twenties

The Stockyards district continued to prosper into the 1920s. In 1921 the Oakland Tribune Yearbook published a detailed article, “Service is the Motto of the Eastbay Packing Houses,” that described Butchertown as it entered the final decade of its golden age.

“It was this need of service to promptly supply Oakland and Berkeley that the first packing house was established just beyond the sparsely settled district, which it was predicted would be many years before any semblance of a city would arise.

On the completion of the first abattoir and the resultant success which followed, other firms erected buildings along the waterfront of upper Emeryville known as the Stockyards district, each specializing in his line, that proper and efficient methods would prevail.

The total amount invested in the packing industries of Emeryville will approach close to two million dollars, a sum considered particularly large when it is known that the market for fresh meats is almost entirely in Alameda County.

Applying to all the packing houses, every carcass is inspected by the Oakland Health inspector, who is always on the premises. Only first-class stock is purchased, and most of the supply comes from Nevada…Bayle, Lacoste & Co., the principal manufacturers of by-products, which are from all packing-house goods, no chemicals being used, estimate an output for the Emeryville district of close to 250 tons of fertilizer and chicken feed per month.

This commercial fertilizer is from the residue of animals, and a blood meal from the blood thereof. Shipments are made all over the world. Considerable tallow, some 400,000 pounds, is rendered monthly from all the plants. Of cattle, 7,500 are killed monthly at the Stockyards, 25,000 sheep and lambs, 7,500 hogs and 1,500 calves. All deliveries are now made by motor vehicles, horse conveyances having been completely abolished. About 200 men are regularly employed in the packing industries, a majority living within a few minutes ride of their work and occupying their own homes.

“Knights of the Cleaver”

Emeryville’s slaughterhouse industry hired not only butchers but also men in numerous other occupations. A study of the 1900 and 1910 U. S. Census reveals that the Butchertown workforce included a large number of specialized jobs, including porter, driver, clerk, foreman, laborer, teamster, butcher, salesman, cook, waiter, weigher, soap maker, carpenter, sheep tender, tanner, hog raiser, bone yards worker, stock raiser, and carpenter. In addition, numerous railroad employees worked as switchmen and freight station lumpers.

Butchertown teamsters drove horse-drawn wagons, loaded with meat, to San Pablo Avenue and then to local East Bay retail meat markets. A considerable number of carpenters worked at the Stockyards continually constructing barns, fences, sheds, and buildings. The butchers. affectionately known as the “knights of the cleaver,” were the backbone of the workforce, and they enjoyed considerable prestige at a time when tradesmen were respected by the general populace.

There were two basic types of butchers. Factory butchers worked in the slaughterhouses; retail butchers worked in local meat markets. Before refrigeration, the factory butchers reduced the steer to half or quarter pieces which were hauled to the retail butchers, where the meat was cut down to smaller portions. The factory butchers often worked long hours under dreadful conditions.

The introduction of assembly line methods to the slaughterhouse industry resulted in a decline in the status and pay of the factory butcher. In early Butchertown, one skilled butcher dressed a side of beef. After automation the skilled butcher was replaced by numerous laborers who each performed a small cutting task that required no particular expertise. However, the role and status of the retail butcher remained undiminished through the decades.

In 1881, San Francisco butchers formed the Journeymen Butchers Protective Association of the Pacific Coast. This fraternal organization incorporated in 1888, and branches of the association were organized in major cities of the state, including San Francisco, Oakland, San Jose, Los Angeles, Sacramento, and Stockton. One may assume that the Butchertown butchers were members of the Oakland chapter. By 1895, the Journeymen Butchers had a membership of over 600. The association provided various benefits for members, including sick pay and payments to dependents in the event of death.

According to a 1917 San Francisco Chronicle article, the lives of the butchers in the 1880s were difficult:

“At that time the butchers had been compelled to work all hours of the day and night, starting to work as early as 3 o’clock in the morning, and quitting at 8 and 9 o’clock at night, every night of the week. On Saturday nights they worked through until 2 or 3 o’clock Sunday morning, and in many cases were compelled to go to the shop again on Sunday at 11 o’clock to carry in meats:”

Another source states that Bay Area butchers originally worked from 16 to 18 hours a day, but that by 1917 this was reduced to 10 hours a day.

In 1901, the Journeyman Butchers of San Francisco organized Butchers’ Local 115 in an effort to improve working conditions. The newly-formed union received a charter from the Amalgamated Meat Cutters and Butchers Workers of North America. All workers associated with the butchering business, including butchers, sausage makers, drivers, and slaughterhouse men, were encouraged to join.

In 1915 the Butchers’ Union maintained an East Bay office located at 387-12th Street in Oakland. It negotiated with employers and reached an agreement which reduced the number of work hours per week. In 1913, the state locals organized the California State Federation of Butcher Workmen in an effort to promote cooperation between local chapters. The Federation sponsored conventions on an annual basis attended by representatives from state locals.

In 1915, the Butchers’ Union signed an agreement with slaughterhouse employers that raised the salary of butchers to “$21 per week for ten hours work per day and eleven hours on Saturday.” In addition to higher pay, one of the goals of the union was to abolish work on Sundays.

Butchers’ Day

Butchers’ Day. an “attempt to show the strength of the trade” and to honor the proud fraternity of meat cutters, was celebrated every year, usually in May, for over two decades. Butchers’ Day was first celebrated in 1894, eight years after the formation of the Journeymen Butchers’ Protective and Benevolent Association. It was sponsored at different times by the Journeymen Butchers, Retail Butchers’ Association of San Francisco, and the Butchers Board of Trade, and was usually held in the East Bay at Shell Mound Park, Oakland Trotting Park, or Idora Park.

On Butchers’ Day all of the retail butcher shops in the Bay Area shut down so butchers could attend the event, along with their families and friends. The celebration began as a simple parade, but expanded over the years to include fireworks, dancing, music, bands, speeches, barbecues, athletic events, foot races, horse racing, literary exercises, and picnics.

The first Butchers’ Day celebration was held on May 23, 1894 in San Francisco. Butchers from San Francisco, Oakland, and San Jose participated. The Oakland butchers, 150 in number, wore their white caps and aprons and marched down Broadway led by a band and a platoon of police. After joining the butcher contingent from San Jose, they took the ferry to San Francisco. Butchers from the various inland cities joined together, and accompanied by bands, marched to Golden Gate Avenue. After disbanding, they proceeded to Golden Gate Park, where a program was held at Festival Hall.

On May 22, 1895, Butchers’ Day festival was held at Shell Mound Park and Oakland Trotting Park. The program consisted of horse races and bicycle races at the Oakland Trotting Park and foot races and dancing at Shell Mound Park. Butchertown was located only a few blocks north of Oakland Trotting Park and Shell Mound Park, which made it convenient for Butchertown residents to attend.

The horse races at the Oakland Trotting Park included a trotting race, a quarter mile horse race, and a one-mile horse race. The program also featured cowboys throwing the lasso, riding wild horses, trick riding, and “picking objects from the ground while under full speed.” Bicycle races around the one-mile track provided additional excitement. The Shell Mound Park activities featured games, sports, speeches, literary exercises, and dancing at both pavilions. Sporting events included boy’s races, girl’s races, egg and ladle races, hurdle races, butchers’ races, and tug-of-war contests. Oakland’s Mayor John L. Davie was present, and he gave an eloquent speech for the occasion.

The 1902 Butcher’s Day celebration was again held at Shell Mound Park and Oakland Trotting Park. The San Francisco Call observed:

“As usual the attendance at the annual picnic given in Shell Mound Park under the auspices of the Butchers’ Board of Trade was extremely large. This year’s picnic was held yesterday. Fully 20,000 people journeyed across the bay to see the races at the Emeryville track given by the ‘knights of the cleaver’ and to enjoy dancing and other pastimes in the park. Every train brought its share. The day was ideal.

The races created a deal of excitement. The betting was very lively. Some very fine horses were entered, and the various heats were closely contested. Over at Shell Mound Park there was a scene of revelry. The place was filled with guests. The pavilion was so crowded that a dancer had his hands full piloting his fair partner about the hall. A band played enlivening dance music while the guests picked their way over the slippery floor. The crowd was a good-natured one and no one complained if his corns were stepped on as he knew he would probably be performing the same trick on someone else.

The picnic was an orderly one. Few if any fistic disputes were held and these were suppressed in quick order and the disputants put off the grounds. At the racecourse hundreds sat in the warm sunshine and watched the sport. There were races for the old and young, fat and lean. Children danced for prizes and young men caroled their best for the edification of the crowd. The fun lasted until 6 o’clock and many would have been dancing yet if the musicians had not taken their departure.

The 1911 Butchers’ Day celebration at Shell Mound Park was considered “one of the most successful ever held by the San Francisco and Alameda county butchers.” The program featured athletic sports which included foot races at Shell Mound track. A race between fat men attracted considerable attention and was reported in the following newspaper article:

“The most amusing race of the day, and the one that caused the greatest interest among the butchers, was the fat men’s race. To be eligible for this event the entrant had to tip the beam at 200 pounds or over. A large field lined up for the race, which was once around the track. At the gun J. J. Kerwin, a midget of 260 pounds, jumped into the lead. He held his place for the first 75 yards, but he was evidently not in form for the hard race A. Crowll gave him. Crowll weighs 220 pounds, and, being in better form than Kerwin, he took the pole and had an easy time for the rest of the race, running like a veteran and winning by five yards. A. Schnucker, a tiny man 230 pounds, won third money.”

The annual Butchers’ Day celebration of 1916 was held at Idora Park in Oakland, an event that attracted a crowd of 50,000. On this occasion a carnivorous crowd of butchers arrived from all over Northern California, and after devouring six tons of meat, they danced the Butcher Tango, a dance created for the occasion. The San Francisco Examiner reported:

“Rib steaks, veal chops, hamburger and beef roasts were entirely forgotten for the day when the Master Butchers of Northern California and their friends, 50,000 strong, occupied Idora Park for their annual butchers’ day celebration yesterday. Members of the association from all parts of the State north of Tehachapi attended the celebration, which was one of the most elaborate and successful affairs ever staged by the organization.

A special dance, labeled the ‘Butcher Tango,’ arranged by W. T. Harper, chairman of the butchers’ day celebration committee, opened the festivities yesterday afternoon in a novel and interesting manner. Two barbecues were held during the day, one at noon and the other in the evening. For this feature of the programme six tons of boneless meat were used, for which preparations had been under way for several days. Two of California’s most famous barbeque chefs were brought from the south, their first trip to this part of the State in thirty years, for the occasion. The two old Spaniards who prepared the vast tonnage of meat for the day were for years chief cooks for the Miller & Lux ranches.

In addition to the two barbecues, a long programme of races and games was presented, with water races and fancy diving and swimming events. Special music was supplied by an augmented band and dancing was held throughout the day and evening.”

After 1916, interest in Butchers’ Day declined and the celebration soon vanished from the holiday calendar.

Hotels of Butchertown

The golden age of Butchertown extended from about 1880 until the beginning of the Depression era. During this fifty-year period, five hotels were built in the stockyards district. Two were constructed in the late 1870s. The first, Roff’s Hotel, opened about 1877 and was located on the north side of Dalton Avenue (now 65th Street). John C. Roff was the owner and proprietor. Previously, Roff had worked as a mate on the “Louise,” a steamer operated by the Central Pacific Railroad. By 1881 Edwin J. Carlie had become the proprietor. Roff’s Hotel remained in business for only a few years, last appearing in the Bishop’s Oakland Directory, 1881-82, suggesting it closed or burned down about that time. No known photograph exists of Roff’s Hotel, but one may assume the building was a wooden structure, as were most of the East Bay hotels of that era.

The Golden Gate Hotel, the second hotel to be built in Butchertown, opened about 1878. William Storm was the original proprietor, but after 1884 J. H. Rourke held this position, and continued to manage the building for several decades while living on the premises. The hotel was located at the northwest corner of Dalton Avenue and Bay Street, next to the Southern Pacific tracks. The three-story, frontier Italianate style building, was 75 feet long by about 30 feet wide, with a porch extending along the south side.

According to an 1878 ad, the hotel offered boarding and lodging at the “most reasonable rates.” Apartments were available “single or en suite,” and meals were served in the dining room. The hotel was equipped with a saloon and a billiard room. Tenants could park their steeds (or nags) at a nearby stable. A small room attached to the east side of the building served as an office for the Southern Pacific Co. and a station for the West Berkeley local railroad.

Most of the tenants of the Golden Gate Hotel worked as butchers or carpenters in the Stockyards district. An 1887 Oakland Tribune article noted:

“At the Golden Gate House, J. H. Rourke, proprietor, corner Dalton Avenue and Bay street, there are about eighteen or twenty boarders who eat the best of soups, mutton and beef with unfailing regularity. Butchers work too hard to get very stout, but they are probably the strongest and most muscular class of artisans in the world, being seldom sick and remarkably long lived.”

The Golden Gate Hotel and Roff’s Hotel functioned as boarding houses for the stockyard employees, and since the Butchertown work force was exclusively male, the hotels catered to a male clientele. Although assaulted by powerful smells and awakened at night by the passing of trains, the boarders of the hotels had the advantage of living close to work.

The Golden Gate Hotel stood in the center of the Stockyards district, surrounded by corrals and slaughterhouses, but, depending where you lived in the building, the rooms offered views of the bay, the hills, the factories, or the countryside. The residents living on the lower floors of the west side looked out upon the corrals and slaughterhouse of U. M. Slater, but boarders on the upper floors had a marvelous view of the San Francisco Bay, with its boats. ships, and ferries, and the magnificent Golden Gate in the distance. Although inured to tedious work and hardened by the brutality of their trade, they no doubt still appreciated the magnificent sunsets at the end of the day. When residents on the east side of the hotel looked out their windows, they saw railroad tracks below and passing trains, the corrals and sheds of Butchertown, the farms and buildings of the Golden Gate District, and on the horizon the Oakland-Berkeley Hills.

The residents of the hotel endured the stench of livestock, the cacophonous sound of animals in nearby corrals–bawling cattle, bleating sheep, snorting hogs, and worse, the cries of animals being killed. After winter rains, the dirt streets turned to mud, and at times a cold west wind blew across the bay. On warm summer days the stagnant air smelled of burning bones, blood, and manure. The casual visitor found this environment unbearable, but the residents developed a tolerance for the barnyard existence of Butchertown.

In the 1890s, the residents of the hotel were mostly butchers and carpenters, a close fraternity of tradesmen who preferred to live in the Golden Gate Hotel, the most prestigious address in Butchertown. The routine of the residents is open to speculation, but one can surmise that returning to the hotel after a long day of work, these rough-hewn men changed out of their dirty clothes and sat down in the dining room for a dinner of soup, meat, and potatoes prepared by the cook, Annie Niedt. The waitress, Margaret McCarty, rushed back and forth from the kitchen to the dining room carrying large trays of hot food. In the absence of female patrons, a boarding house atmosphere prevailed with boisterous and profane talk.

Afterwards the tenants played a quiet game of billiards or pool, or smoked a cigar, and then, having retired to the saloon, conversed about the events of the day over a cold glass of beer. After retiring to their rooms late at night, they lit kerosene lamps, and perhaps read a newspaper or a book of poetry by Alfred Tennyson, Oscar Wilde, or Walt Whitman, or wrote a letter to a loved one far away.

The Golden Gate Hotel continued to flourish into the twentieth century. By 1908. J. H. Rourke had changed its name to Stockyards Hotel, a more appropriate appellation considering the surroundings, and about the same time Dalton Avenue was renamed 65th Street. James H. Rourke remained the proprietor of the Stockyards Hotel until it closed in 1925, and then retired to live in a house at 6101 San Pablo Avenue in the Golden Gate District. The hotel remained in business for about 47 years, surviving much longer than the other hotels in the community. The closing of the Stockyards Hotel ended the era in which slaughterhouse employees lived in the center of the slaughterhouse district.

Stockyard Exchange

The Stockyard Exchange, the third hotel to operate in Butchertown, opened in the 1880s. Located at the foot of Dalton Avenue (65th Street) north of the Golden Gate Hotel, this two-story wooden structure originally functioned as a hotel and boarding house. It also may have served as an office building for local and out-of-town livestock entrepreneurs. A January 20, 1887 Oakland Tribune article relates:

“The Stockyard Exchange which is owned by John Maher. also receives a goodly number of boarders and in a quiet way attends to the sporting interests of the little community. The best meals are served here, and there is a good deal of transient travel at this terminus of the cattle interest. The hotels (Golden Gate and Stockyard Exchange) are aristocratic and scorn the idea of five cents for a glass of beer, but just as excellent board and lodging can be obtained here as in any section of Alameda County.”

John Maher served the “sporting interests” of the community by holding boxing matches, dog fights, and cock fights in a barn behind the hotel. These activities were illegal and at times the place was raided by the Alameda County Sheriff. In 1890 Maher was arrested and charged with conducting dog fights on the premises. The case went to a jury, but a friendly jury found him innocent.

The Oakland Tribune resorted to hyperbole by stating that the Golden Gate Hotel and Stockyard Exchange were “aristocratic” when in reality both structures did not compare architecturally or in any other way to the truly grand hostelries in the Bay Area. The exact year the Stockyard Exchange closed is not known.

Three additional hotels were built in Butchertown in the twentieth century. The Eagle Hotel, located at the southwest corner of 63rd Street and Green Street (now Hollis) opened in about 1908. The Eagle had a liquor store that sold whiskey, choice wines, and cigars. Charles Roques was the first proprietor, but by 1916 it was operated by Peter and Baptiste Bouzout. The Eagle is not listed in the city directories of the early 1920s, but the hotel reappears as the New Eagle Hotel in the 1924 city directory, suggesting that it closed for a brief period and then reopened, perhaps after remodeling. E. Bengas was the proprietor of the hotel during the final years of its existence. It closed in the late 1920s.

The L. & L. (Loustalot and Loustalot Hotel) was owned by Rosalie Loustalot, the widow of Pierre Loustalot, the French butcher. The hotel opened about 1914 and was located at 1318-65th Street next door to the Loustalot residence. The L. & L. remained open for only a few years. closing about 1920. The Cushing Hotel, the last hotel to be built in Butchertown, was located at 1318-65th Street and opened about 1920. The proprietor, Leroy Cushing, had previously operated a saloon at 6479 San Pablo Avenue. The Cushing closed about 1924.

In addition to hotels, there were also lodging houses in Butchertown. In the 1890s, Mrs. A. Sherry operated a lodging house at the corner of Dalton and Bay Streets which was also equipped with a saloon.

By the tum of the century, a residential district had emerged in the eastern section of Butchertown in the vicinity of Green Street (now Hollis). The 1903 Sanborn map shows houses on both sides of Green Street. Gradually the meat-packing industry expanded, displacing houses on the west side. However, numerous Butchertown employees lived outside the Stockyard district; many preferred to live in the Golden Gate community, an upscale neighborhood located only a few blocks east of Butchertown.

Railroads

The construction of railroads had a powerful impact on the growth of Butchertown. The Northern Railway was the first railroad to serve the unincorporated area north of Oakland that later became Emeryville. Construction of the railroad began in 1876 and was completed two years later. It originally reached from Oakland to Martinez, a distance of 31 miles.

The Northern Railway consolidated with Southern Pacific in 1898. The line was extended after the turn of the century, and it eventually became the famous Overland Route, over 700 miles of track stretching from Oakland to Ogden. From Martinez the Overland Route went through Sacramento, then to Truckee, over the Sierras, eastward through Nevada, across the salt flats terminating in Ogden, Utah.

The Northern Railway tracks ran along the shoreline of the East Bay. The Stockyards district was built next to the railroad tracks because the meat-packing industry depended on the railroad for the transportation of livestock.

Nineteenth century Butchertown had a passenger station and a freight station. The latter was located on the east side of the tracks at the foot of Dalton Avenue, now 65th Street. The main line passenger trains roared through Butchertown without slowing down, but the local trains stopped at the Southern Pacific Stockyards Station.

A local railroad, the West Berkeley line, operated on Northern Railway tracks from Shell Mound Park to Delaware Street in West Berkeley. This steam train consisted of a locomotive and two passenger coaches. The first locomotive on this line was named the “Theodore Judah,” a 4-2-2 engine built in 1863. The West Berkeley local, which began service in 1877, went back and forth on the east side track, stopping at the Southern Pacific Station at the Golden Gate Hotel at the foot of Dalton Avenue, now 65th Street. The West Berkeley Branch Railroad remained a steam train until it ceased operation in about 1914.

In 1912, Southern Pacific opened a new line that split from the main line at Shell Mound, continued north on Doyle Street in Emeryville, crossed Dalton Avenue and followed Ninth Street through Berkeley and Albany. Called the Ninth Street line, it turned east on Solano Avenue and terminated at the Thousand Oaks Station in Berkeley, carrying passengers from Berkeley to the Oakland pier where they caught a ferry to San Francisco. The cars were painted a bright red, and the train became known as the Red Train.

The Dalton Station on the Ninth Street line served the Butchertown neighborhood. It stood one block east of Green Street and appears to have been a simple, open sided structure with a roof. The Red Trains also served the Butchertown neighborhood until 1941.

Traffic on the Southern Pacific line increased after the tum of the century. By 1914 six tracks ran through Butchertown. The two outside tracks functioned as spur tracks for industry. The main line consisted of two eastbound tracks, one freight and one passenger, and two westbound tracks, one freight and the other passenger. In addition to these six tracks, there were numerous spur tracks that served the many Butchertown industries. Trains passed every day at various speeds on all six tracks, making it dangerous for men or livestock to cross the tracks, especially in the rain or fog. Although Butchertown has now disappeared, the main line tracks survive. Freight trains and Amtrak passenger trains still roll through Emeryville, 120 years after the building of the Northern Railway. Because a large stretch of’ the bay shoreline has been filled in, the Southern Pacific tracks are now several blocks from the shore. The new Emeryville Amtrak Station is only a short distance from the original Butchertown Southern Pacific Station.

Decline of Butchertown

The closing of two well-established firms during the Great Depression signaled the beginning of the Stockyard District’s long sixty-year decline. Alden and Agnew, wholesale butchers at 6541 Bay Street. closed in 1930. Oakland Meat & Packing Co., the largest slaughterhouse and meat-packing plant in Emeryville, shut down in 1937. The demise of Oakland Meat & Packing Co. resulted in a drastic reduction of the Butchertown workforce.

The completion of the San Francisco-Oakland Bay Bridge in 1936 and the subsequent construction of the East Shore Highway had a decisive impact on the Stockyards district. The new highway, built one thousand feet west of the original shoreline, funneled northbound Bay Bridge traffic across the East Bay tidelands. The water trapped between the highway and the shore created a large lagoon.

Mayor Al LaCoste wanted Emeryville to expand westward into the bay, and this highway project provided a perfect opportunity. Soon after completion of the new highway, the tidelands between the original shoreline and the East Shore Highway was filled in. The old slaughterhouses could no longer dump refuse into the bay. This bay fill project increased the area of the city by over 150 acres, but forever changed the geography of the Stockyards district, by opening up the tidelands to development.

World War II generated a demand for meat that stimulated business in Butchertown, but the war also had a negative side effect. The U.S. Government used the corrals for parking military vehicles during the war, limiting the number of livestock the feed lots could accommodate. The encroachment of the military into the Stockyards district set a precedent followed by industry. During the forties and fifties, factories unrelated to the meat-packing industry were built in the district, including Grove Valve, Ryerson Steel, and Andrews Lumber Co.

During this long period of decline, two early Butchertown factories were destroyed by fire. In 1940, Bayle-LaCoste & Co. on 63rd Street caught fire and several buildings burned to the ground. After the fire a new plant was rebuilt about 300 feet north of the old site. In 1958. a disastrous fire destroyed the main brick building of the T. W. Corder Wool Pulling Works at the foot of 67th Street. Although some of the smaller buildings survived the fire, the main brick structure was seriously damaged and had to be razed. The factory was forced to close, and eventually warehouses were built on the property.

Final Years

Early Butchertown was dependent on the railroad to transport livestock to the district. The introduction of refrigeration encouraged the decentralization of urban slaughterhouses to rural areas. Slaughterhouses located in the country found it profitable to ship processed meat to urban markets in refrigerated trucks. By the 1950s, Butchertown had become an anachronism. T. W. Corder explained this revolution in his autobiography:

“Most people nowadays in the meat packing business have found it more profitable to build slaughterhouses in the country near the livestock supply rather than trucking the cattle, sheep and hogs all the way into the city.” Rural-based meat-packing plants also took advantage of cheap non-union labor. Emeryville’s Butchertown suffered a fatal decline, as one by one, the meat-packing plants either shut down or relocated. Grayson-Owen went out of business in 1952 after 75 years in Emeryville. Golden West Meat Co. closed two years later.

LaCoste Meat Co. and Peterson Tallow Co. managed to survive through the sixties and seventies. The latter, at 63rd and Overland Streets, operated as a tallow, meat scraps, and fertilizer business. The company changed its name to Peterson Mfg. Co., Inc. around 1967. Unable to buy animal by-products from local meat-packing firms, the company dispatched trucks around the East Bay to restaurants, hotels, and meat markets to pick up animal grease, tallow, bones, and scraps for their rendering plant. They went out of business in 1986.

LaCoste Meat Co. survived for a few more years at the Bay Street address. By the 1980s, only the north end of the plant was occupied by the firm, and Farmer Packing Co. leased the south end. LaCoste Meat Co., the last factory to operate in Butchertown, closed in 1989, and the building was razed soon after. The destruction of this plant marked the end of Butchertown’s 115-year existence as a slaughterhouse and meat-processing center.

This story originally published in 1996 for the Emeryville Centennial Celebration and compiled into the ‘Early Emeryville Remembered’ historical essays book.